The World's Most Flexible, Most Sustainable Innerduct

As consumer awareness and concern about climate change and the environment grow, companies are taking steps to reduce their carbon footprint and demonstrate their commitment to sound environmental stewardship. Designed specifically for the network construction industry, MaxCell® is a flexible fabric innerduct that provides cable pathway functionality at a fraction of the cost, labor, energy, space and carbon emissions versus HDPE innerduct.

A Pathway To Sustainability

For every million feet of single-cell MaxCell installed instead of HDPE innerduct, the resulting carbon savings are 644 metric tons CO2 equivalent. These Green House Gas (GHG) savings are equal to the annual GHG emissions from over 126 passenger vehicles on the road or over 72,000 gallons of gasoline consumed. Over 600 million feet of MaxCell innerduct have been successfully installed around the globe. If you want to increase your productivity, improve your bottom line and reduce your carbon footprint, MaxCell is the solution.

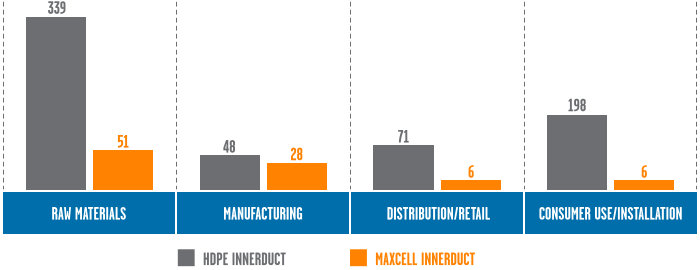

MaxCell worked with ICF International to calculate a reduction of GHG emissions for MaxCell vs. traditional rigid HDPE innerduct in 2011, using a Lifecycle Analysis (LCA) model that included both public emissions data and proprietary manufacturing data for both products. In 2021, MaxCell looked to update this LCA, to confirm that the product still provided similar supply chain GHG reductions vs. HDPE Innerduct, and retained Bent Branch Strategies to complete this LCA re-evaluation. MaxCell's carbon footprint is 81.24% less than HDPE innerduct (660 kg CO2 equivalent per 1,000 feet of single cable pathway).

Carbon Footprint Comparison

(KG CO2 equivalent per single cable pathway)